Each centrifugal compressor has a maximum pressure it can reach for specific inlet conditions that will cause the airflow to reverse and surge shutting off the compressor to avoid damage from the resultant vibrations.

Centrifugal air compressor surge.

Now we will see how the surge starts in a compressor.

Compressor surge only occurs in dynamic compressors axial and centrifugal due to their nature.

Centrifugal compressor surge is seen as a very dangerous and detrimental phenomenon in compressed air systems dangerous because it causes the compressor to vibrate and detrimental because it causes damage to the compressor parts.

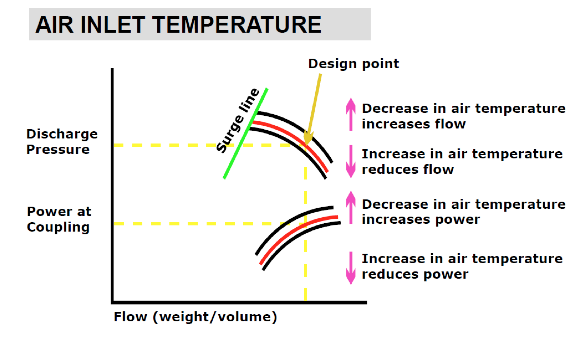

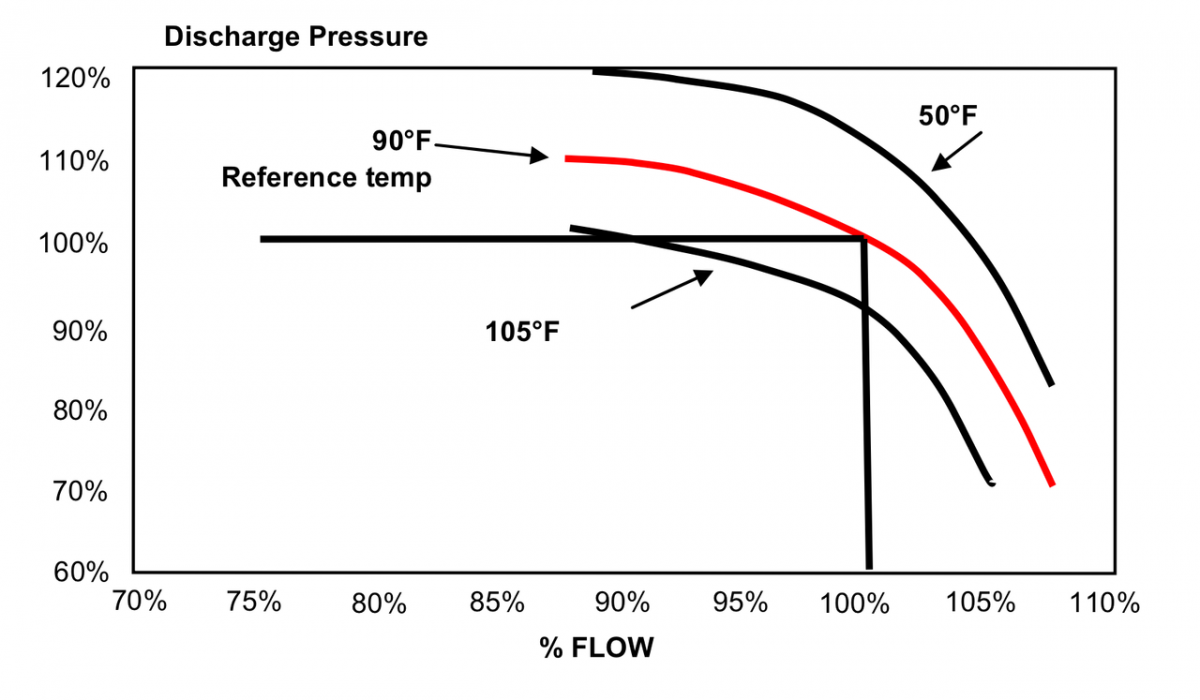

If the density drops due to higher inlet temperature the volume flow actually reduces.

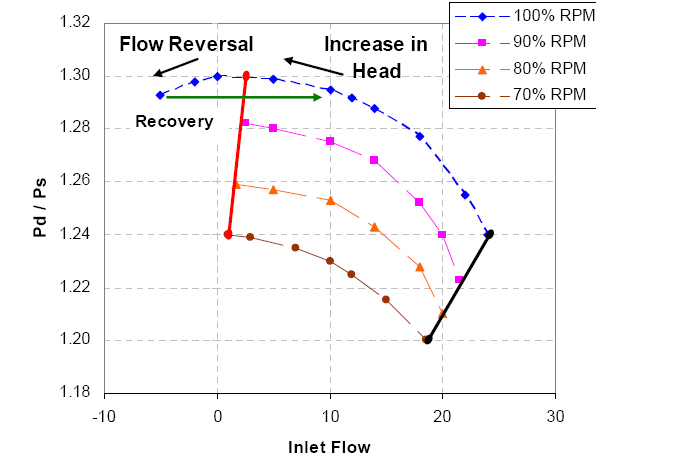

The surge is starting with the instant flow reverses shown in the.

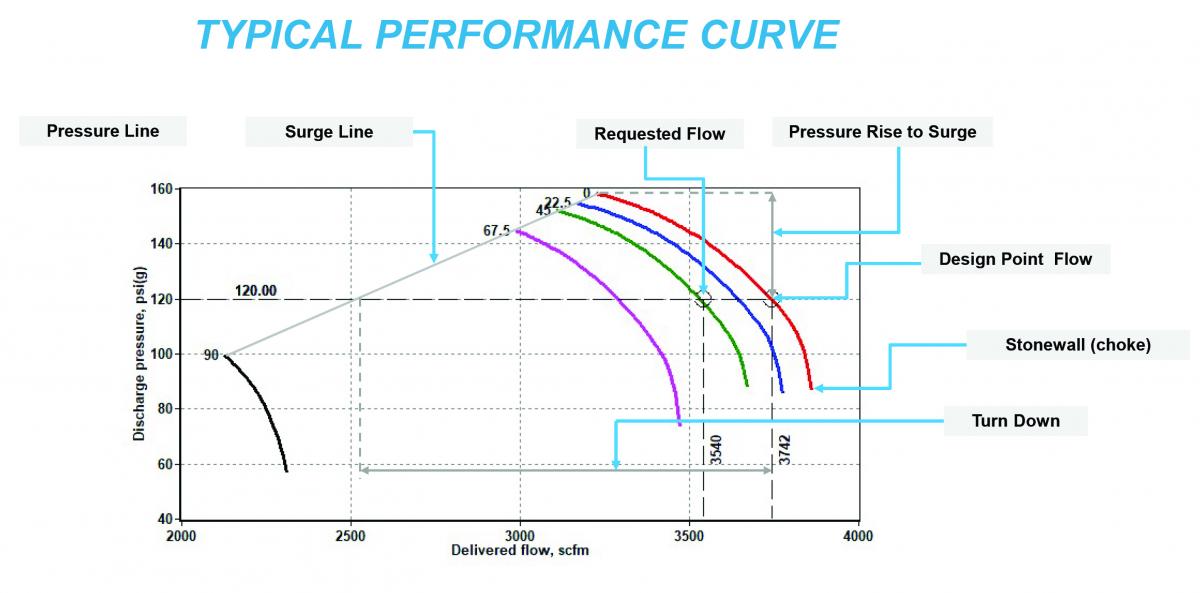

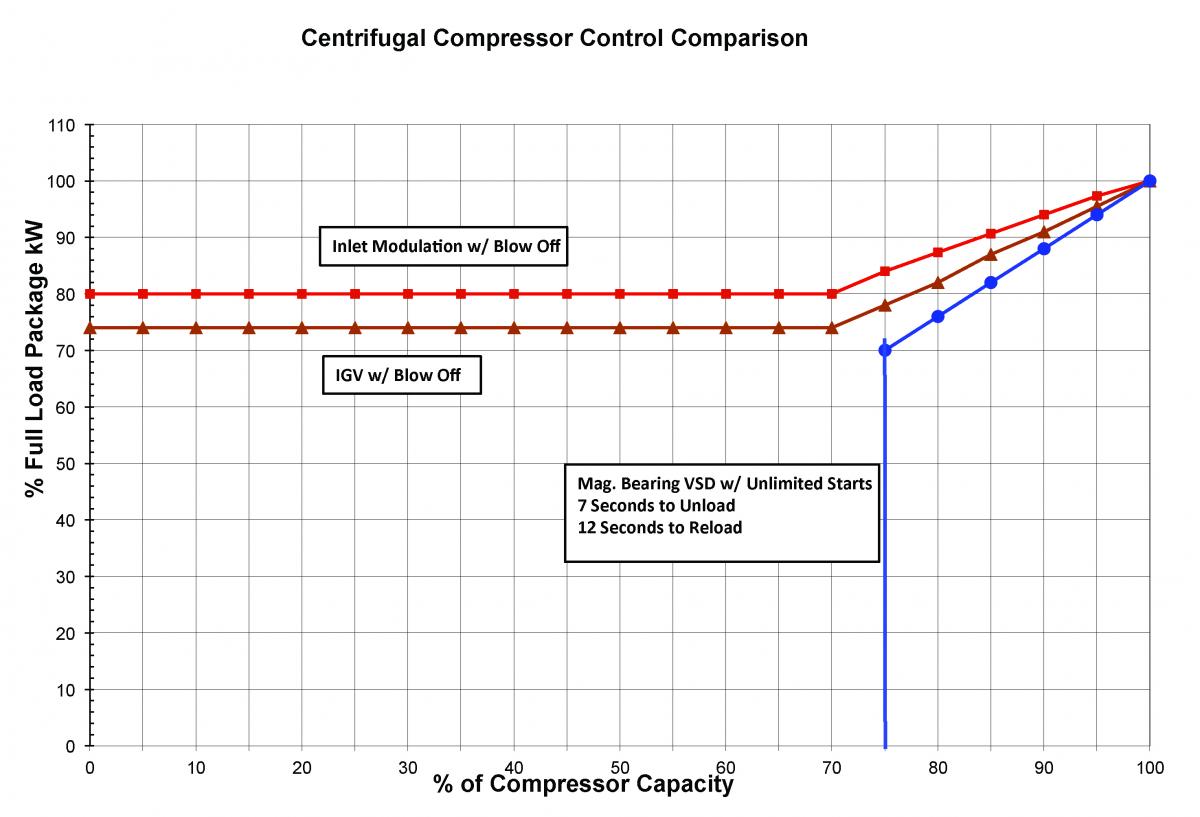

As more compressed air is produced than needed the centrifugal compressor must unload or deliver less air to avoid over pressure.

The addition of the turbo air and msg centrifugal compressors expands our market coverage to higher pressure higher flow and process gas compression applications.

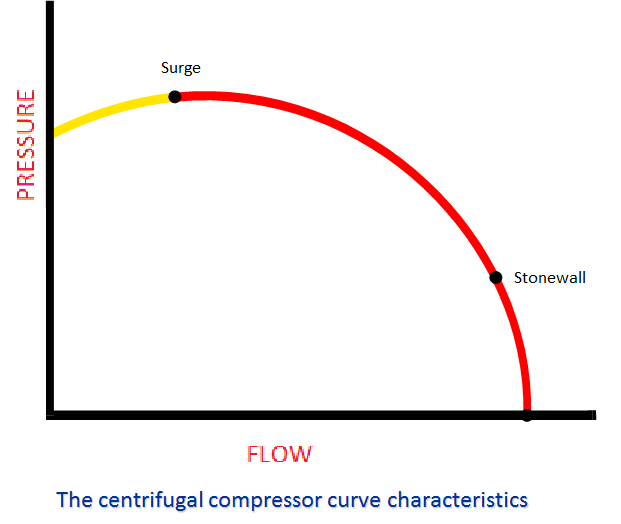

Compressor surge is a form of aerodynamic instability in axial compressors or centrifugal compressors the term describes violent air flow oscillating in the axial direction of a compressor which indicates the axial component of fluid velocity varies periodically and may even become negative.

Compressor capacity should be stated at plant conditions which are actual cubic feet per minute acfm.

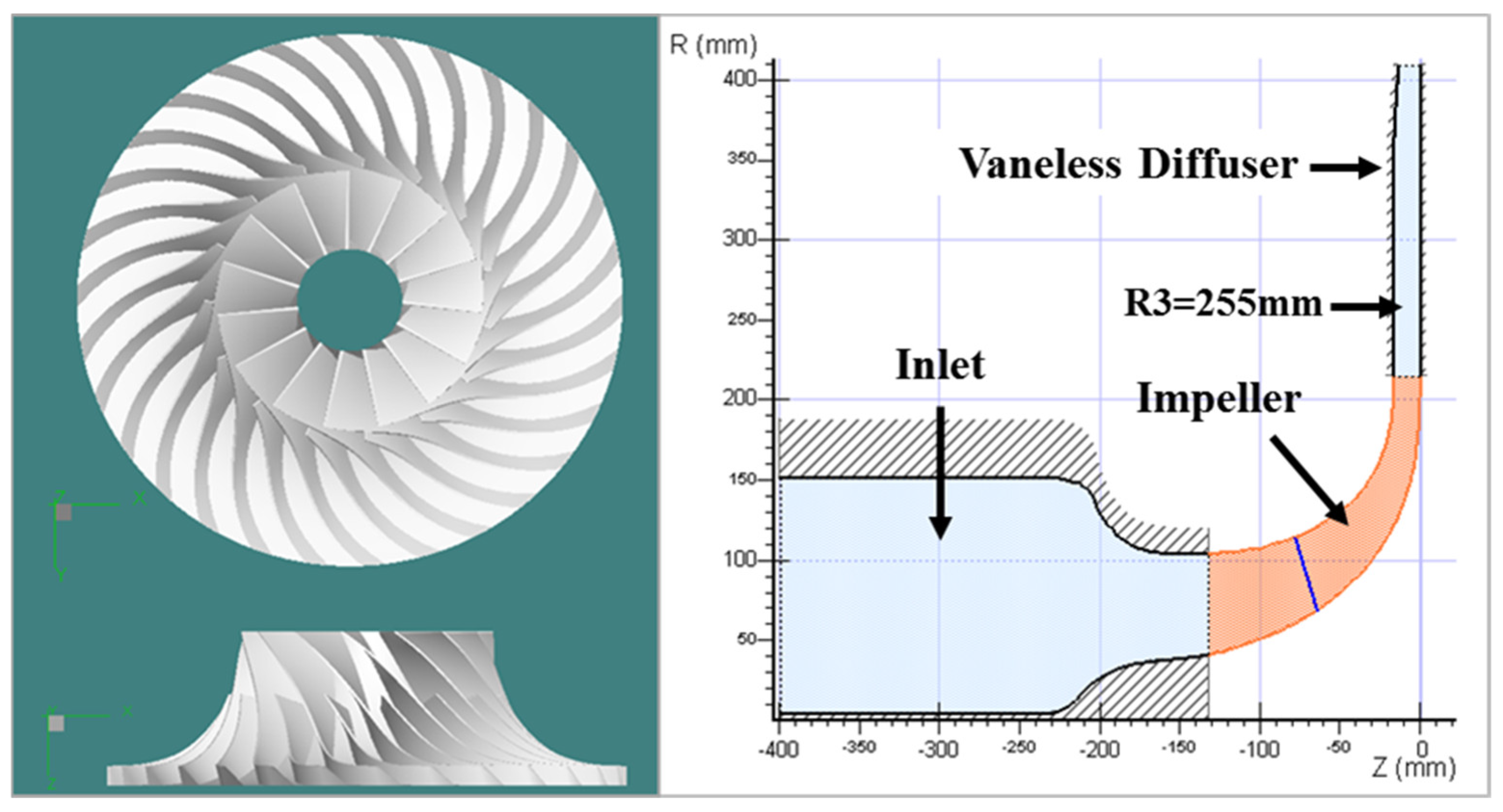

They achieve a pressure rise by adding kinetic energy velocity to a continuous flow of fluid through the rotor or impeller this kinetic energy is then converted to an increase in potential energy static pressure by slowing the flow through a diffuser.

A centrifugal air compressor will surge earlier based on amps on a hot day than on a cold day.

Compressor surge control using anti surge valve asv cold gas recycle.

Centrifugal air compressor basics key concepts centrifugal compressors are most effective when running at full capacity.

When a centrifugal compressor surges there is an actual reversal of gas flow through the compressor impeller.

Actually the working principle of a centrifugal compressor is increasing the kinetic energy of the fluid with a rotating impeller.

Centac c800 centrifugal air compressor.

Centrifugal air compressor delivered flow or capacity is dependent on inlet density.

The fluid is then slowed down in a volume called the plenum where the kinetic energy is converted into potential energy in form of a.

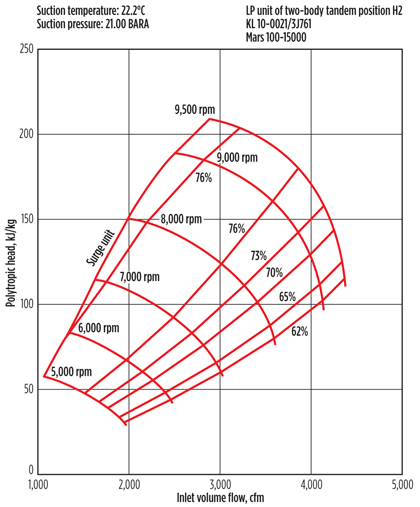

Choke and surge occur at the extreme ends of the performance curve and should be avoided.

The lower mass flow reduces the ability of the first stage.

The chief protecting agent of a centrifugal compressor is the anti surge line valve that recycles cold gas from the discharge side cooler back to the suction scrubber to keep the operating point away from the surge line.

Surge is defined as the operating point at which centrifugal compressor peak head capability and minimum flow limits are reached.

Hot gas recycle valve.